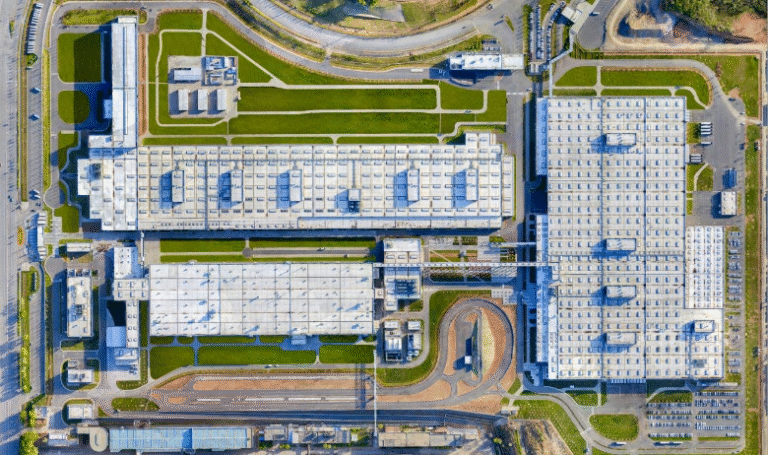

Company Profile

RSIT is a leading provider of integrated system solutions for intelligent manufacturing in the industry. The company focuses on the research and development, production and sales of intelligent in-plant logistics, warehousing, sorting and fire protection systems in industrial production. With the goal of comprehensively enhancing the digitalization, automation, intelligence and greenness of customer enterprises, it effectively applies leading technologies such as AI, DTS, IIC and IoT. Develop high-quality products that meet the needs of multiple industries in production, logistics, warehousing, green development and other aspects, and help customers achieve intelligent manufacturing, safe manufacturing and green manufacturing.